At its essence, Scitek specialises in vacuum technology, providing a variety of instruments and components tailored for diverse physics applications. Our offerings span a wide spectrum of vacuum pumps, gauges, chambers, valves and other components, catering to needs ranging from rough vacuum to ultra-high vacuum. Furthermore, Scitek offers complimentary solutions such as mass flow control, leak detection and glovebox technology.

Plasma Physics

Plasma physics, exploring charged particle behaviour, reveals insights into fusion energy, astrophysics, and more. Plasma Technologies merge theory and practice, driving innovation and scientific exploration across fields. They assist industries with precision modifications, coatings, and processing using ionized gases. Vital in electronics, healthcare, energy and many other areas, they enhance performance and sustainability. Applications include creating ultra-thin layers, sterilising medical tools, and boosting adhesion.

Leak Detection

Tracer gas leak detection is a method used to locate leaks in various systems by introducing a tracer gas, like helium or hydrogen, into the system. Pfeiffer Vacuum offers advanced solutions for tracer gas leak detection. They offer a comprehensive suite of leak solutions encompassing various detection methods. Pfeiffer Vacuum’s solutions ensure product integrity, safety, and environmental compliance, making them vital across industries.

Vacuum Gauges

Vacuum gauges measure the pressure within a vacuum system which is often crucial for controlling processes. Various technologies, such as Pirani, Penning, cold cathode, and capacitance diaphragm gauges are employed. Pirani gauges measure pressure through thermal conductivity, while Penning gauges use ionisation. Cold cathode gauges rely on electron emission, and capacitance diaphragm gauges gauge pressure by measuring diaphragm deflection. These methods exploit gas behaviour under different pressures. Pfeiffer Vacuum, a leader in vacuum technology, offers a range of measurement solutions, ensuring precise pressure analysis for diverse industrial applications.

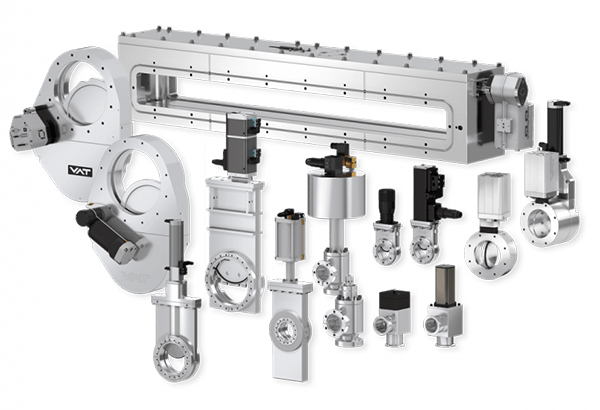

Vacuum Valves

Vacuum valves are integral components in controlling gas flow within vacuum systems ensuring optimal pressure levels. They are also often used for chamber isolation, item transfer or chamber access. Common valve types include gate valves, butterfly valves, and ball valves. Gate valves utilise a sliding plate, while butterfly valves use a rotating disc. Ball valves feature a spherical closure. Our partners Pfeiffer Vacuum and VAT, renowned industry leaders, offer a range of high-quality vacuum valves.

Rough Vacuum to Ultra-High Vacuum

The range between rough vacuum and ultra-high vacuum (UHV) covers a wide span of pressure levels within vacuum systems. Rough vacuum typically spans from atmospheric pressure (1013 mbar) down to approximately 10e−3 mbar. Ultra-high vacuum, on the other hand, extends from 10e−7 mbar to 10e−11 mbar or lower. Rough vacuum is used in various industrial processes, vacuum filtration, and basic laboratory operations, offering a substantial reduction in gas molecules compared to atmospheric conditions. High vacuum enables more precise applications such as chemical vapor deposition and physical vapor deposition. Ultra-high vacuum (UHV) is an extreme level of vacuum, that requires meticulous system design, ultra-clean conditions, and specialised equipment. It’s crucial for highly sensitive applications like surface analysis, electron microscopy, and particle accelerators. Achieving UHV involves minimising gas molecules to levels approaching those found in outer space, enabling research and processes that demand minimal molecular interference. Scitek offers a wide range of technologies including diaphragm pumps, rotary vane pumps, turbo pumps, ion pumps and more.

Mass Flow Control

Mass flow control is a technology that precisely manages the rate of gas flow. It involves adjusting flow to a set rate regardless of pressure or temperature changes. These devices ensure accurate gas flow in applications from industry to research. Our partner Alicat offers industry leading mass flow meters and controllers.

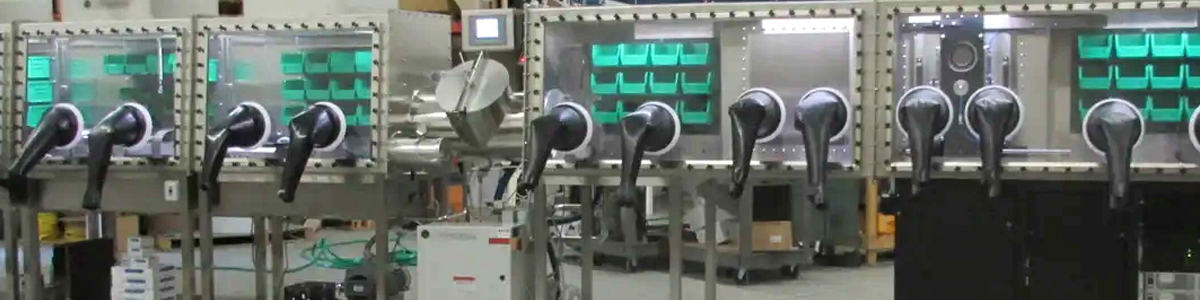

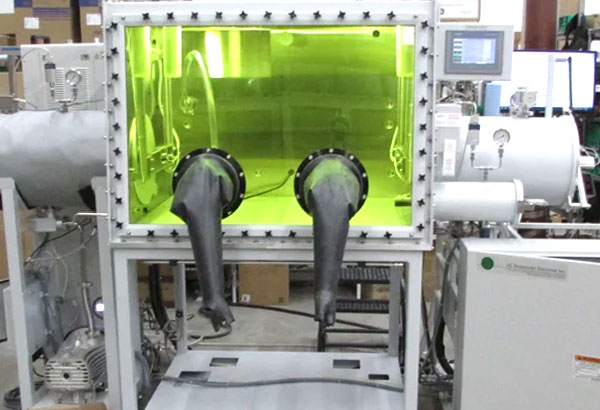

Glovebox Technology

Glovebox technology involves creating a controlled environment in a sealed chamber with gloves for external manipulation. This enables handling of sensitive materials in a controlled atmosphere, shielding them from moisture, oxygen, and contaminants. Between our partners LC Technology Solutions and Etelux we can offer glovebox technology for basic and advanced from pharmaceuticals to electronics. These solutions ensure precise control over the environment, safeguarding materials and enabling research and manufacturing processes with stringent atmospheric requirements.

Gas Analysis

Mass spectrometry identifies and quantifies gas components based on their mass-to-charge ratios. This process involves ionising gas molecules, separating ions based on mass, and measuring their quantity. The technology is widely used in research, environmental monitoring, and industrial applications. Pfeiffer Vacuum’s mass spectrometers provide valuable insights into gas composition, enabling precise quality control and process optimisation for various industries. Their range detects and measures trace gases, isotopes, and impurities with exceptional accuracy.

Thin Film Deposition

Material is heated in a vacuum until it vaporises and then condenses onto a substrate to form a thin film. This technique is suitable for materials with low melting points and is used for optical coatings, thin film transistors, and in the fabrication of various electronic components.