Scitek have a range of equipment for the chemistry laboratory. Our core expertise is vacuum and this finds use in our rotary evaporators, vacuum dryers, vacuum concentrators, freeze dryers and more. We also supply a broad range of chemically resistant vacuum pumps, valves and gauges, including the unique VacuuLan system for integration into laboratory benches and fume cupboards. Scitek also supply related equipment for liquid thermal regulation, glass chemical reactors, chemical synthesis stations as well as overhead mixers and magnetic hotplate stirrers.

Solvent Evaporation

Rotary evaporators and centrifugal concentrators are essential tools in chemistry labs using vacuum to evaporate solvents at moderate temperatures. Rotary evaporators utilize a rotating flask, under vacuum, in a temperature-controlled bath to efficiently evaporate solvents. The precise control of vacuum and bath temperature enable fast solvent removal while preserving delicate samples. Centrifugal concentrators employ rapid spinning to prevent sample cross contamination and bumping from multiple samples in a batch. Typically, samples are presented to the system in vials or test tubes after a purification step. Both devices use vacuum for the concentration of solutions at moderate temperatures, streamlining processes and enhancing productivity in the modern chemistry laboratory.

We supply rotary evaporators from Heidolph and Genser with options from basic – but high-quality – to fully automated systems that fill and empty automatically. Sizes range from compact benchtop to floor-standing models. Our centrifugal concentrators are from Genevac and available in a number of different versions to suit users. Genevac offer unique technologies such as their DriPure system which protects from sample cross contamination. The new EZ2 Bionic is perfect for high throughput laboratories looking for automated loading of the concentrator.

Solvent Drying

Solvent dryers or purifiers play a vital role in laboratories by effectively removing water from solvents. These devices employ molecular sieve material to achieve exceptional levels of dryness in the low ppm range, ensuring the purity and reliability of solvents for delicate reactions where anhydrous solvent is required. The systems from LC Technologies are modular from a single solvent dryer that fits inside a fume cupboard, to a large floor standing system for 7 solvents.

Freeze Drying

Freeze dryers, essential in laboratories, preserve perishable materials by removing moisture via sublimation. This process involves freezing the substance and then creating a vacuum to facilitate direct transition of ice to vapor. By maintaining the structural integrity of delicate samples, freeze dryers yield dehydrated products with excellent quality. Martin Christ freeze dryers are cutting-edge solutions combining innovative technology with user-friendly features and highest quality. With customizable programs, vacuum control, and temperature management, Martin Christ freeze dryers cater to diverse research and industrial needs. They find application in pharmaceuticals, biotechnology and food industries, providing reliable and consistent results for preserving substances, enhancing shelf life, and facilitating the development of high-quality products.

Thermal-Regulation

Thermoregulators are critical instruments when precise heat transfer fluid based temperature control is required. Huber offer thermal control systems from water-baths to units with integrated pumps for various applications from automotive, food, polymer and pharmaceutical applications. Huber offer temperature control from -120°C up to +425°C. Huber’s unique Unistat systems are the benchmark solution for dynamic temperature control.

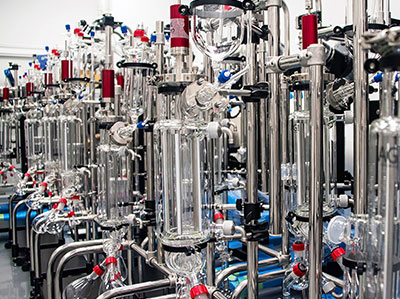

Chemical Reactors

Chemical reactors are essential tools for controlled chemical processes in labs, chemistry and pharmaceutical industry. Asahi Glass offers a diverse range of glass reactors for larger processing volumes. Radley’s provides innovative reactors with customizable features for laboratory and scale up. Radley’s AVA system offers advanced software integration, automation and data monitoring. Together, these suppliers cater to diverse research and production needs, enabling efficient and accurate chemical reactions, from small-scale experimentation to industrial applications.

Chemical Synthesis

Radleys specializes in a diverse range of laboratory chemical synthesis systems. Their offerings include automated platforms for controlled reaction processes, lab-scale reactors, parallel reaction stations and accessories for hotplates and stirrers. These systems cater to varying scales of synthesis, from small single reactions to parallel setups, ensuring reproducibility and process optimization. With a strong emphasis on safety and green chemistry, Radleys solutions integrate software control with hardware to automate workflows and accelerate research.

Mixing and Stirring

Heidolph offers a comprehensive suite of laboratory benchtop equipment for mixing, stirring, shaking, and liquid pumping applications. Their range includes magnetic stirrers, overhead stirrers, and shakers with controllable power for various viscosities and volumes. Additionally, their peristaltic pumps allow liquid transfer and circulation.

Local Area Vacuum Networks VacuuLan

Vacuubrand offers a modular platform for connection of multiple applications to one vacuum pump. The systems typically span a number of fume hoods and vacuum taps on benches within one laboratory. Unlike house vacuum solutions the VacuuLan system prevents cross contamination and interference by means of integrated highly effective non-return valves. All components are made from fluorinated plastic materials offering long term solvent compatibility far beyond house vacuum systems. Waste solvent can be collected and disposed of responsibly instead of accumulating in long vacuum lines potentially forming dangerous mixes.

Calorimetry

Our Setaram systems are widely used for the analysis of drug stability and compatibility. The technique precisely measures the heat flow associated with temperature-induced transitions in a sample to investigate the thermal behaviour of drugs and their formulations.